Penetration Depths

Penetration Depths

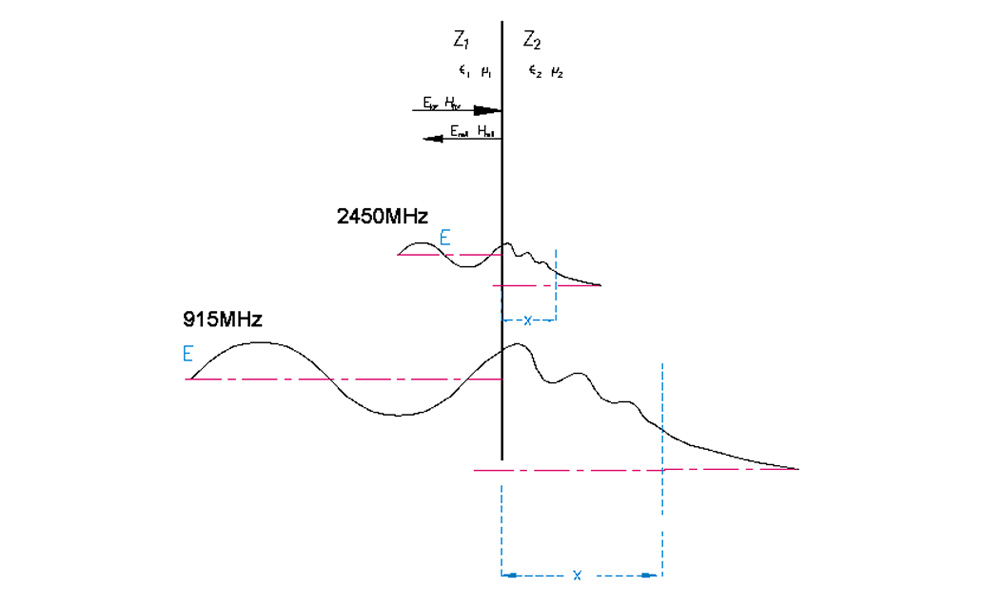

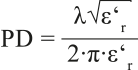

The penetration depth is calculated according to equation (2), which shows how it depends on the dielectric properties of the material. The penetration depth is used to denote the depth at which the power density has decreased to 37 % of its initial value at the surface.

Materials with higher loss factor εr’’ (imaginary part of the complex permittivity) show faster microwave energy absorption. The power density will decrease exponentially from the surface to the core region.

f = frequency, measured in Hz

εO absolute dielectric constant (DC) = 8,85x10-12 As/Vm

с = 3x1010cm/s speed of light

Ε = electrical field strength, measured in V/m

ε = εO * ( εr’ - j εr’’ ), complex dielectric constant

tan δ = εr’’/εr’

δ = dielectric loss angle, measured in degrees

λ0 = wavelength, measured in, λ0 =c / f

Table 1 shows the penetration depth values of various materials. It should be noted that the penetration depth of the electric field strength is sometimes reported in the literature, with a value which is twice as high.

| Material | Temperature in °C | Penetration depth in cm |

|---|---|---|

| water | 45 | 1,4 |

| water | 95 | 5,7 |

| ice | -12 | 1100 |

| bread | 25 | 2 ... 5 |

| potato, raw | 25 | 0,9 |

| mashed potato | 25 | 0,8 |

| peas, carrots | 25 | 1 |

| meat | 25 | 0,9 ... 1,2 |

| paper, cardboard | 25 | 20 ... 60 |

| wood | 25 | 8 ... 350 |

| caotchouc | 25 | 15 ... 350 |

| hollow glass | 25 | 35 |

| porcelain | 25 | 56 |

| polyvinylchloride20 | 20 | 210 |

| epoxy resin (Araldite CN-501) | 25 | 4100 |

| teflon | 25 | 9200 |

| quartz glass | 25 | 16000 |

Table 1. Penetration depths of microwave energy of various materials at 2450MHz

Products with huge dimensions and high loss factor may occasionally overheat within a considerably thick layer on the outer surface. To prevent such a phenomenon the power density should be chosen so that enough time is provided for the essential heat exchange between boundary and core. If the thickness of the material is less than the penetration depth, only a fraction of the supplied energy will be absorbed.

Nevertheless, this only applies if the energy, which is not absorbed, spread away from the material after leaving it. The unabsorbed microwave radiation is, however, reflected from the metal walls of the application chamber and penetrates the material more than once.

Another consideration of the power density needed for microwave heating is that appropriate field strength values must be maintained inside the application chamber. Under atmospheric conditions, these are generally several orders of magnitude smaller than the breakdown strength for dry air (30 kV/cm). In the case of vacuum applications, or whenever the air inside the applicator is very moist, the electric field strength should be limited to an extent that prevents ionisation of the air, in order to avoid enormous damages that could be caused to both product and equipment.