Corporate

We have successfully carried out the development, construction and marketing

of industrial microwave plants since 1970.

About us

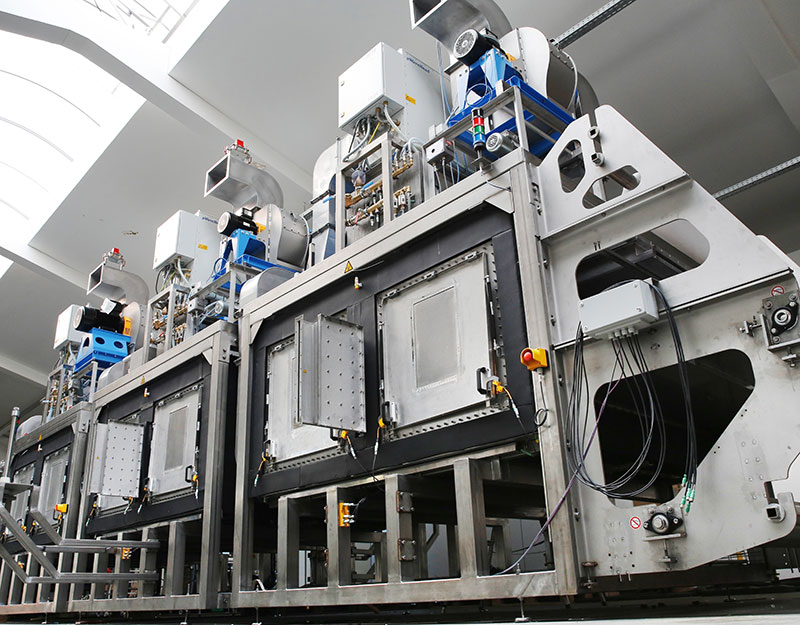

We have successfully carried out the development, construction and marketing of industrial microwave plants since 1970.

For each client-specific development or project design of our plants, we exploit our extensive microwave technology know-how, backed up by many years of experience in systems engineering and process technology.

As we work closely in cooperation with our clients we are able to respond quickly to any clients demands. With proficiency and enthusiasm we meet the challenges of this interdisciplinary team-work.

Whenever there are high demands on product quality and throughput rate, microwave plants are the better alternative compared to conventional heating systems. A vast number of completely new production processes were only able to be realised by the utilisation of microwave energy.

With the microwave systems technology that we have developed we take pride in offering our clients an advantage in an increasingly competitive global market.

We look forward to your inquiry...

At our work place we produce in two seperate factory halls (1st hall of 1.000 sqm for administration and production, 2nd hall of 450 sqm for production and pilot operation). At our site approx 20 trial plants are available with different applicator designs for process investigation.

Even though our main business is focused on Europe, we also have installations in Asia, Africa and in US. A network of worldwide partners enables us to give the best of support at any location.

We have competent and experienced consultants in charge of each project from first contact up to the servicing of our plants at the customers work place.

The development of a process according to each individual specification can be started in our fully-equipped laboratories in order to guarantee fast and reliable results.

Modelling of applicator designs using the software program Ansoft at the Technical University of Hannover and the Technical University of Valencia.

- Vacuum plants (batch & continuous)

- Dryer (batch & continuous up to 20kW)

- Chamber ovens

- Flow Heater for viscous Products

- Continuous heater for strand products, sheets and webs

- Sintering plants up to 1600°C providing a vacuum level down to 1E-6bar

DKE Congress 27th Apr 2005 in Frankfurt Speech "Strategic Impact of Standards in the global Competition"

86th meeting of the DKE Committee K 362, December 2023

| Score | Subject |

|---|---|

| 1,58 | Quality of plants |

| 1,80 | Process stability of plants |

| 2,02 | Price performance ratio of plants |

| 1,27 | Competence of staff |

| 1,29 | Quality of support in case ofproblems |

| 1,39 | Response time in case of problems |

| 1,85 | Quality of documentation |

Rating:

1 - very good, 2 - good, ... 6 - bad